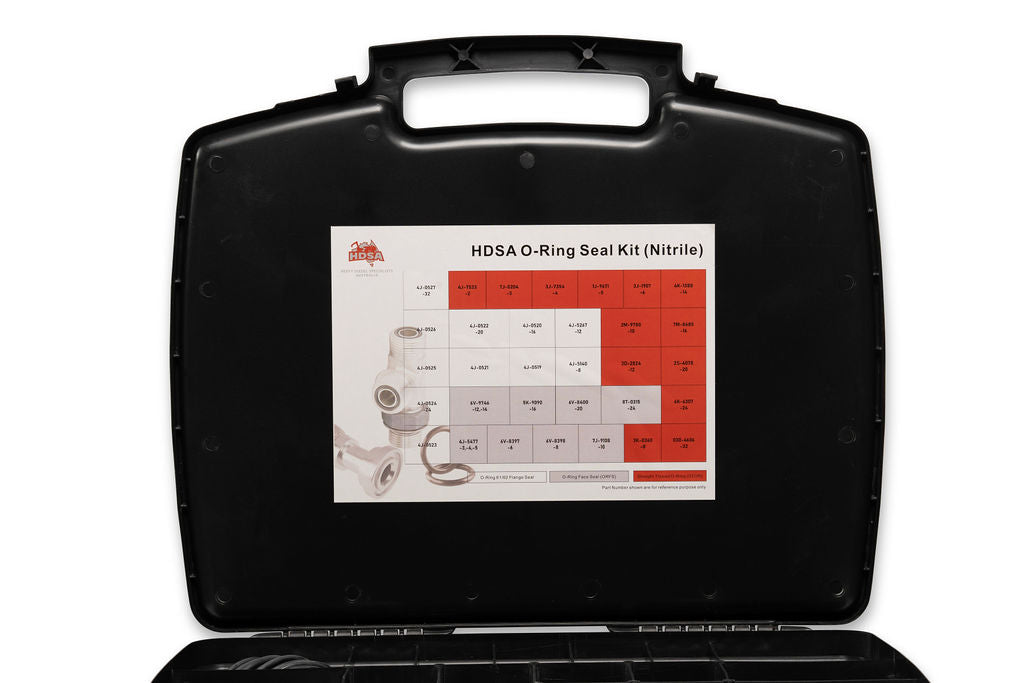

- Description

- OEM Equivalent O-Rings

- Suit STOR, ORFS and code 61/62 flanges

- 570pc kit

✅ STOR – Straight Thread O-Ring

-

4J-7533 — Qty 20 — Dash 2

-

7J-0204 — Qty 20 — Dash 3

-

3J-7354 — Qty 20 — Dash 4

-

1J-9671 — Qty 20 — Dash 5

-

3J-1907 — Qty 20 — Dash 6

-

3K-0340 — Qty 20 — Dash 8

-

2M-9780 — Qty 20 — Dash 10

-

3D-2824 — Qty 20 — Dash 12

-

4K-1388 — Qty 20 — Dash 14

-

7M-8485 — Qty 20 — Dash 16

-

2S-4078 — Qty 20 — Dash 20

-

6K-6307 — Qty 20 — Dash 24

-

030-4606 — Qty 10 — Dash 32

✅ ORFS – O-Ring Face Seal

-

4J-5477 — Qty 20 — Dash 3, 4 & 5

-

6V-8397 — Qty 20 — Dash 6

-

6V-8398 — Qty 20 — Dash 8

-

7J-9108 — Qty 20 — Dash 10

-

6V-9746 — Qty 20 — Dash 12 & 14

-

6V-8400 — Qty 20 — Dash 16

-

8T-0315 — Qty 20 — Dash 24

✅ Flange – O-Ring 61/62 Flange Seal

-

4J-5140 — Qty 20 — Dash 8

-

4J-5267 — Qty 20 — Dash 12

-

4J-0519 — Qty 20— Dash 12

-

4J-0520 — Qty 15 — Dash 16

-

4J-0521 — Qty 15 — Dash 20

-

4J-0522 — Qty 15— Dash 20

-

4J-0523 — Qty 15 — Dash 20

-

4J-0524 — Qty 10 — Dash 24

-

4J-0525 — Qty 10 — Dash 24

-

4J-0526 — Qty 10 — Dash 24

-

4J-0527 — Qty 10 — Dash 32

Uses of Nitrile Duro 90 D-Rings in Earthmoving Equipment

Nitrile (NBR) Duro 90 D-Rings are engineered for heavy-duty sealing applications where components are exposed to high pressure, hydraulic oils, and mechanical stress. Their hardness rating of 90 durometer makes them ideal for demanding earthmoving and heavy-diesel environments that require exceptional extrusion resistance and long-term durability.

Where Nitrile Duro 90 D-Rings Are Commonly Used

-

High-pressure hydraulic systems including pumps, cylinders, valve blocks, and control circuits.

-

Diesel, engine-oil, and transmission-oil sealing points where strong fluid compatibility is essential.

-

Static and slow-moving dynamic interfaces that experience substantial mechanical load or pressure spikes.

-

Heavy-duty connectors, JIC fittings, and flange interfaces found across mobile plant and earthmoving machinery.

Why Duro 90 Nitrile Is Selected

-

Superior extrusion resistance due to the higher hardness (90A), preventing seal blowout in high-pressure systems.

-

Excellent compatibility with petroleum-based fluids, including hydraulic oil, diesel fuel, engine oil, and gear oil.

-

Good abrasion resistance, making it suitable for equipment operating in harsh, dirty environments.

-

Reliable performance across a broad temperature range, typically from –30 °C to +120 °C depending on compound formulation.

-

High tear strength and compression resistance, supporting long service life under heavy mechanical loads.

Limitations and When Not to Use Nitrile Duro 90

-

Not ideal for high-temperature environments above the recommended range; elevated heat may harden or crack the material.

-

Limited resistance to ozone, UV and outdoor weathering compared with silicone or EPDM.

-

Less suited to aggressive chemicals such as brake fluids, certain additives, or highly aromatic fuels.

Practical Examples in Earthmoving Equipment

-

Hydraulic cylinder end caps, piston interfaces, and rod-side sealing locations subject to high fluid pressure.

-

High-pressure supply and return line connections, particularly where extrusion risk is present.

-

Drivetrain and engine-oil system fittings requiring robust oil-resistant sealing.

-

Pump housings and valve manifolds that experience continuous hydraulic pressure loads.

Material-Selection Guidance

-

Choose Nitrile Duro 90 for high-pressure, oil-immersed environments where mechanical load and extrusion resistance are critical.

-

For high-temperature or outdoor weather-exposed locations, consider other elastomers better suited to heat or UV resistance.

-

Ensure the hardness and material type match the system’s pressure rating, fluid type, and operating conditions.