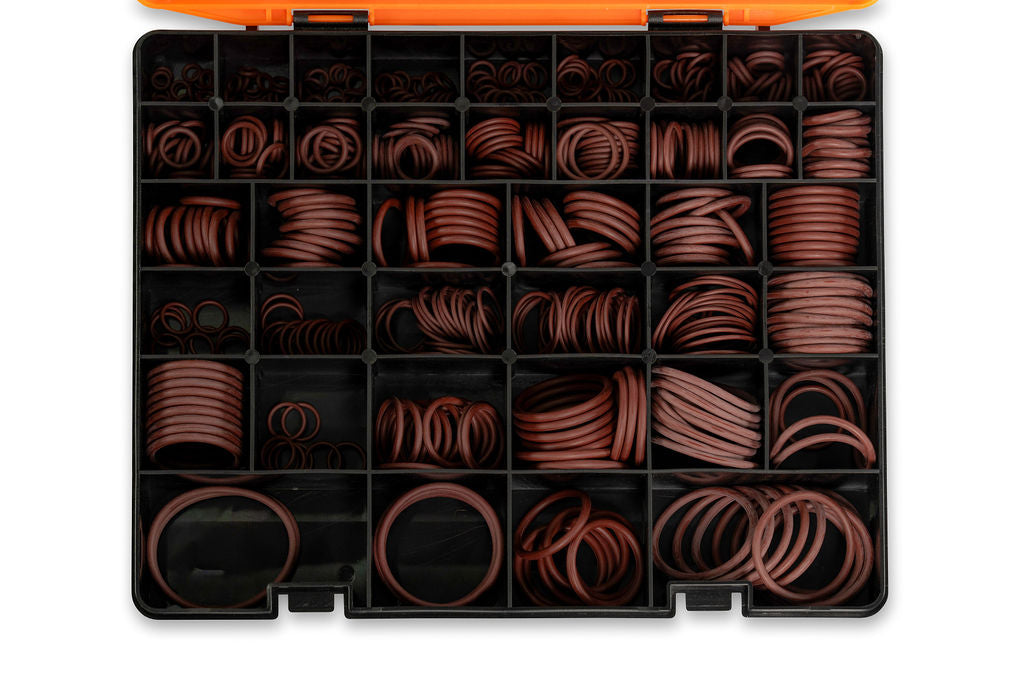

- Description

- What's included

- SKFM Material exceeds OEM standard

- Suitable for construction and civil equipment

- 530pcs

Part number and QTY

-

P3 — 15 pcs

-

P5 — 15 pcs

-

P6 — 15 pcs

-

P7 — 15 pcs

-

P8 — 15 pcs

-

P9 — 15 pcs

-

P10 — 15 pcs

-

AS013 — 9 pcs

-

P12 — 15 pcs

-

P12.5 — 15 pcs

-

AS014 — 8 pcs

-

P15 — 15 pcs

-

P16 — 15 pcs

-

P18 — 15 pcs

-

P20 — 15 pcs

-

P21 — 15 pcs

-

AS015 — 12 pcs

-

P22A — 9 pcs

-

AS210 — 15 pcs

-

P24 — 8 pcs

-

P25 — 9 pcs

-

AS214 — 15 pcs

-

P26 — 9 pcs

-

P29 — 9 pcs

-

P11 — 25 pcs

-

P14 — 25 pcs

-

AS018 — 25 pcs

-

AS021 — 25 pcs

-

AS025 — 12 pcs

-

AS219 — 15 pcs

-

P32 — 9 pcs

-

P22 — 15 pcs

-

A912 — 15 pcs

-

P35 — 9 pcs

-

G40 — 9 pcs

-

P30 — 8 pcs

-

G50 — 2 pcs

-

G45 — 6 pcs

-

P38 — 15 pcs

-

G40 — 2 pcs

-

G60 — 2 pcs

Uses of SFKM O-Rings in Earthmoving Equipment

SFKM O-rings are high-performance fluoroelastomer seals designed for extreme temperature, chemical exposure, and demanding fluid environments found across heavy-diesel and earthmoving machinery. This material provides superior resistance to aggressive oils, fuels, and hydraulic fluids, making it suitable for the harshest operating conditions.

Where SFKM O-Rings Are Commonly Used

-

High-temperature engine components, including fuel systems, turbocharger areas, and hot oil circuits.

-

Hydraulic systems using advanced or synthetic hydraulic fluids that would degrade nitrile or standard elastomers.

-

Fuel injection systems exposed to modern diesel blends, bio-diesel, and high-temperature fuel return lines.

-

Sealing locations with chemical exposure, including coolants, oils, and additives.

-

Static and dynamic seals where long-term compression resistance and chemical stability are critical.

Why SFKM Is Selected

-

Exceptional chemical resistance to petroleum oils, synthetic lubricants, diesel fuel, biodiesel, gear oils, and many aggressive additives.

-

Very high temperature tolerance, typically from –20 °C up to +200–230 °C depending on grade.

-

Excellent compression-set resistance, ensuring the seal maintains its shape under long-term heat and pressure.

-

Superior resistance to hardening and degradation, even with constant exposure to hot oils and fuels.

-

Outstanding durability in harsh, contaminated environments, common in earthmoving and heavy-diesel equipment.

Limitations and When Not to Use SFKM

-

Not suited for very low-temperature applications (below –20 °C, depending on grade), where elasticity may decrease.

-

Not compatible with certain amine-based fluids such as some refrigerants or special brake fluids.

-

Higher material cost than nitrile or silicone, making it best reserved for applications that require its performance advantages.

Practical Examples in Earthmoving Equipment

-

High-temperature hydraulic pump seals using advanced or high-performance hydraulic oils.

-

Fuel system seals including high-pressure diesel injection, injector return lines, and fuel pump housings.

-

Engine and transmission oil seals located in areas with sustained high heat.

-

Turbocharger and exhaust-proximate sealing points where both heat and chemical exposure are severe.

Material-Selection Guidance

-

Choose SFKM O-rings when the application involves high temperature, aggressive oils or fuels, or long-term chemical exposure.

-

For moderate temperatures and standard oils, nitrile or HNBR may be more economical.

-

Always verify fluid compatibility and operating conditions to ensure the correct elastomer is selected.