- Description

- Hi-temp silicone o-rings

- OEM quality

- 149pc kit

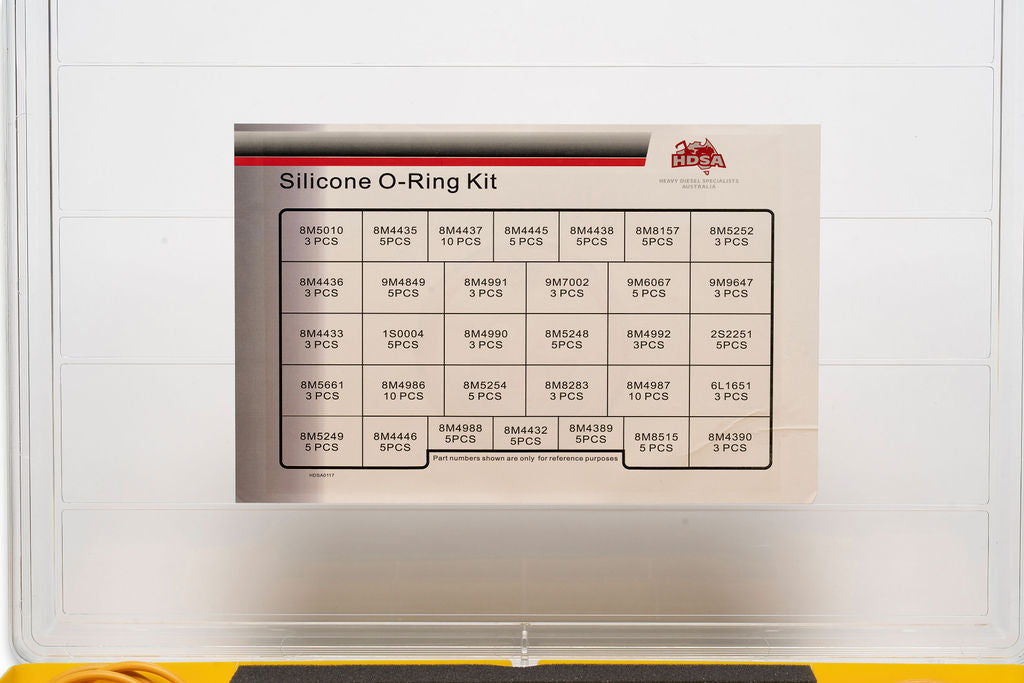

Kit Includes

-

8M-5010 – 3 pcs

-

8M-4435 – 5 pcs

-

8M-4437 – 10 pcs

-

8M-4445 – 5 pcs

-

8M-4438 – 5 pcs

-

8M-8157 – 5 pcs

-

8M-5252 – 3 pcs

-

8M-4436 – 3 pcs

-

9M-4849 – 5 pcs

-

8M-4991 – 3 pcs

-

9M-7002 – 3 pcs

-

9M-6067 – 5 pcs

-

9M-9647 – 3 pcs

-

8M-4433 – 3 pcs

-

15-0004 – 5 pcs

-

8M-4990 – 3 pcs

-

8M-5248 – 5 pcs

-

8M-4992 – 3 pcs

-

2S-2251 – 5 pcs

-

8M-5661 – 3 pcs

-

8M-4986 – 5 pcs

-

8M-5254 – 5 pcs

-

8M-8283 – 3 pcs

-

8M-4987 – 10 pcs

-

6L-1651 – 3 pcs

-

8M-5249 – 5 pcs

-

8M-4446 – 5 pcs

-

8M-4988 – 5 pcs

-

8M-4432 – 5 pcs

-

8M-4389 – 5 pcs

-

8M-8515 – 5 pcs

-

8M-4390 – 3 pcs

Uses of High-Temperature Silicone O-Rings in Earthmoving Equipment

High-temperature silicone (VMQ/PVMQ) O-rings are commonly used in earthmoving and heavy-diesel applications where sealing components must withstand elevated temperatures while maintaining flexibility and stability.

Where High-Temp Silicone O-Rings Are Commonly Used

-

High-heat, low-pressure sealing points such as certain transmission, torque-converter, and driveline service locations.

-

Static seals in areas exposed to substantial radiant or conductive heat (near exhaust components, turbo systems, or high-temperature housings).

-

Environmental and weather-exposed seals needing excellent ozone, UV and aging resistance.

-

Components subject to frequent temperature fluctuations, where silicone’s low-temperature flexibility helps maintain seal integrity.

Why Silicone Is Selected

-

Excellent high-temperature resistance—typically up to around 200 °C, depending on compound grade.

-

Superior low-temperature flexibility compared with many other elastomers.

-

Strong resistance to ozone, oxygen, and long-term weather exposure, making it suitable for equipment that operates outdoors in harsh environments.

-

Good compression-set properties, allowing the seal to maintain shape and performance under prolonged heat.

Limitations and When Not to Use Silicone

-

Not ideal for high-pressure hydraulic circuits where sealing stress is high; other elastomers generally perform better under high pressure.

-

Reduced resistance to petroleum-based oils and fuels compared with materials such as nitrile, HNBR or FKM.

-

Less suited to dynamic sealing surfaces with continuous movement or abrasive contamination.

Practical Examples in Earthmoving Equipment

-

Heat-exposed transmission or converter housings with moderate pressure.

-

Static covers, access plates, inspection ports, and similar components that encounter heat but minimal oil immersion.

-

Auxiliary systems where temperature is the main stress factor rather than pressure or fluid type.

Material-Selection Guidance

-

Use silicone O-rings for high-temperature, low-pressure, low-oil-exposure sealing environments.

-

For high-pressure or oil-immersed applications, select other elastomers designed for fuel and hydraulic-oil compatibility.

-

Always match seal material to the specific operating conditions—temperature, pressure, fluid type, and mechanical load.